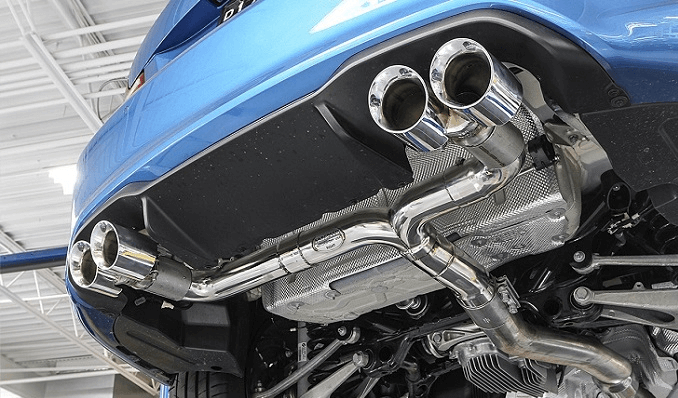

Exhaust system modifications produce readily accessible engine efficiency gains. In essence, wide diameter pipes and bolt-on kits act as a gateway to increased performance. One moment, though, these alterations only work properly if the car’s engine capacity is matched with the right exhaust system. Otherwise, you reach a point of diminishing returns where performance gains flat line. Here are some handy tips for avoiding this horsepower plateau.

Squeeze the Engine for Extra Horsepower

If the exhaust system is open to modification, then so is the engine. Properly establish the engine’s capabilities before turning your attention to the exhaust system. Turbochargers and customized cold-air intake mods involve extra parts, so keep that added expense in mind. If that added expenditure doesn’t ring your bell, then pull the vehicle into your local garage for a full computer tune-up. Basically, push the engine’s power train to its limits before going to work on the breathing channels.

What about Engine Capacity?

There’s a capacity number stamped on the engine or emblazoned on the car paneling. When you encounter it, you store it away in the back of your mind, but maybe you never give it any further consideration. It becomes one of those stored little facts that float to the surface of your mind every so often. That’s fine, except you’ll need to know a bit more if you seriously intend matching a new exhaust system to your engine.

A Dictionary-type Definition

Engine capacity, also known as sweep volume or engine displacement, refers to the amount of space swept by the pistons inside their cylinder casings. Measured in liters, bigger numbers equal more space for the fuel and air to mix. As a general rule of thumb, more power is generated when this value is larger.

Balanced RPM Management

Ideally, the potential exhaust system replacement kit would match the generated torque and the capacity of the engine across all RPM bands by switching bores, but multiple sets of pipes aren’t exactly practical. Instead, a balance is struck by selecting a bore that complements this capacity rating. Enthusiast versions target a more exaggerated performance profile, though, a higher RPM band that delivers aggressive torque characteristics.

Understand the engine’s characteristics and the full meaning of the engine capacity rating. Next, associate this key knowledge with mods that improve the torque of the engine at the source. Finally, research branded exhaust systems so that their aggressive performance characteristics can be matched to the capacity of the engine.

Trufit Exhaust

437 Warrigal Road,

Moorabbin, VIC 3189

Australia

Areas serviced: Melbourne

Tel: 03 9555 5688

Trufit Exhaust on Google Maps

Trufit Exhaust on Google Search

Source: This Post “Tips for Choosing the Right Exhaust System that will Match Your Engine Capacity” appeared first on “Trufit Exhaust“